TheScientificTriangle

What about the environment and science

19 sustainable materials for building in 2024

Liten to the audio below

The world is evolving and deteriorating, natural resources are becoming scarce while artificial resources are increasing manifold around us. Artificial resources are basically manmade materials and off late, there is a huge spike in these goods and materials around us. Building and construction debris is increasing manifold owing to the population’s steep curve. In such situations, we are here today to explore 18 sustainable materials for building homes and workplaces in 2024.

It is estimated that almost 8.5 billion tons of plastic is currently present in the world which is about the size of 55 million jumbo jets. Artificially produced fibers are also accounting for this plastic mass of which 8 to 10 million end up in the oceans every year. You can imagine the amount of microplastics available in the sea and what amount we consume everyday when we skim out a fresh harvest of fish.

More than 500 years will be needed to degrade the current plastic masses available around us. There is a steep rise in plastic production and in 2021 alone according to Statista data, 400 million tons of plastic was manufactured compared to 2 million tons in 1950. The very first plastics can still be around is what scientists across the world predict.

Major highlights around plastic leading to a shift in the construction industry

| Years to decompose the current plastic content | 500 years from now |

| Plastic amount total | 8.5 billion tons |

| Ocean debris amount | 8 to 10 million tons |

| Amount manufactured in 2021 | 400 million tons |

| Plastic amount in 1950 | 2 million tons |

| Plastic bottles purchased each year | One million |

| Plastic grocery bags each year | 5 trillion bags |

| Annual shipment industry plastic consumption | $600 billion in 2021 |

| Annual plastic waste | 350 million tons |

| Plastic generation prediction by 2060 | 1 billion metric tons |

With factors influencing the market other than plastic’s increased footprint, below you find a few more reasons.

Factors influencing the construction shift other than the rise in plastic burden

With these factors contributing to differing choices, you can only see how people are evolving;

- increased carbon footprint of concrete buildings,

- sand shortage and stricter rules around the sand business,

- cement production cost price increase and

- lack of good mud for brick production, the building production home is manifold now compared to where it was in the last 10 years.

What can you do about it? Most architects and builders are designing and using alternative materials to add to the sustainability score. Thus, here we will discuss a few sustainable materials for building in 2024 that can help you immensely when thinking of creating your own space.

- Stones have found a way again

Even though we no longer stay in stone houses, but, you can still make houses from stones. They just do not add to the difference but are being considered by many architects and civil engineers as cheap and ready-made sustainable materials for building resources.

Mentionable designers using stones as a sustainable material for building;

- Earthitects– India

- Peter Rich Architects– South Africa

Why should you build with stones? Here are a few essential benefits;

- Low carbon emission is the call of the hour and stones are one of the best sustainable materials for building to work in 2024.

- You can find stones to be extremely durable to heat, cold, water, fire, bugs, and rots.

- Stones themselves have a different structure and design and you don’t need anything else.

- Insulation capacity is much higher than concrete.

- Non-toxic in every way. Do you know the paint you use at home is toxic and the air around becomes toxic? What you breathe matters the most.

2. Mud houses

Old days are gone but mud houses have not lost their charm. With the current architects making beautiful designs out of mud, you can only dream of a differently built house. Mud is one of the most sustainable building materials and can be of wonderful use in the coming year.

You’d ask if bricks are made of mud too then why not use mud bricks? Brick manufacturing itself is done in a kiln and the temperature and carbon waste increase hugely. Carbon emission lessening is the first target, the next being the reduction of waste production from building a concrete structure apart from the aim to make buildings more durable.

Notable Architects putting mud to good use in India;

- Sketch Design Studio

- Karnath Design Studio, Surajkund, Haryana

The benefits of using mud as a prime building material include;

- Mud walls can withstand earthquakes better and also cause less damage to lives upon facing one.

- Insulation property is high for them.

- Fire and heat resistant

- Low production and maintenance cost

- Extremely natural soundproofing abilities

- Absolutely eco-friendly in nature

Image credit: Planet Custodian

3. Scrap Construction

Can you imagine a house built of scraps? From your child’s pencil shavings to left out ice cream sticks to your scrap wood and plywood?

Houses are being constructed of waste debris and these houses are constructed as strongly as your concrete houses.

Michael Reynolds Earthship is a beautiful start to this incredible construction journey. We all know Can Brick and the imagination lightening up at its mention and the mere wandering of how it might be staying in such a house.

Benefits are encircling around the cheap availability of construction materials and the immensely decreased cost of the house’s production.

- There is no shortage of garbage around us and we might soon be living in our homes surrounded by many forms of garbage. Using them in the right way can not only reduce it from overpouring into us.

- Amazing shapes and designs are easy.

- Most importantly, evacuation will not be mentally painful as a man won’t be worried about leaving behind a cheap home he once lived in rather than an opulent palace of gold, silver, and concrete.

Image credit: Earthship

4. Bamboo is the next generation sustainable material for building

Bamboo has received international attention in various countries where it is widespread like Japan, India, Vietnam, and even China.

Vo Trong Nghia and his work with bamboo is amazing. Why would someone use a green resource when the wood is going out of the market slowly, someone might argue in their heads.

The reason lies in the fact that bamboo has a few advantages over other trees and thus growing and using them is being largely considered. We will have a close look at the reasons below;

- Bamboo grows really fast and all you need is suitable soil and enough sunlight plus a little water. Some species of bamboo can grow as much as 2.91 feet in a single day and that is according to the Guinness World Records. Since growing them is easy and fast, the world is considering this green plant for building and construction.

- The high tensile strength of bamboo is considered as essential in construction and can be used as scaffolding when creating skyscrapers.

- Bamboo is earthquake resistant and with the Eurasian plate moving towards the Asian counterpart, you can expect more and more Earthquakes. Recently, Iceland recorded 1000 earthquakes before volcanic eruption prediction and also other earthquakes all around the world. It might only grow in the coming times.

- An extremely cheap alternative bamboo can significantly bring down the cost of construction and that way helps more and more people to own houses and build homes.

- Bamboo is a versatile resource and has more than one use.

Image credit: Dezeen.com

5. Nature living material

Building homes of living materials is another way and in recent times, it is being used as a sustainable material for building in 2024.

Trees are a beautiful resource and can be woven together to make homes that not only provide you with a perfectly natural environment but also bring you close to Nature.

Microorganisms are also another way of building homes and are a part of the living building material ensemble.

Different heterotrophs and autotrophs are currently being used in building construction and right now there are several ongoing researches and research papers around it.

Bacterial scaffolding is being targeted and Synechococcus sp. PCC 7002 is one of the currently studied bacterial species. Ideally even Escherichia coli is also used in building and housing construction.

The benefits of using living materials as sustainable materials for building in 2024 are not sans its benefits.

- No toxic waste creation is possible with the living material when used for sustainability.

- Energy efficiency is higher when we use living building materials as they can prevent heat escape thereby reducing the overall cost spent on heating our houses.

- Green roofs can not only act as low carbon emitters but also can be used for capturing increased carbon content available in the atmosphere.

- Air quality can improve as the inside air will be non-toxic and free of any kind of chemical content or heavy particulate matter.

- Water as a resource can become scantier with passing days and these living buildings can conserve water effortlessly.

Image credit: Atlasobscura.com

6. Editor’s choice: Steel as a sustainable material for building

Steel is not on the side of concrete when it comes to building houses. Steel is a green source and a sustainable material for building and it will remain that way in the coming years.

It is one of the cliche products in the market contributing towards green production. Almost 8% of the carbon dioxide production in the atmosphere is from the production of steel and yet, post production it is one of the most sustainable materials for building.

Iconic architecture and Frank Gehry are synonymous.

The benefits of using steel, a man made material, are many and if the fine balance between its production and use are not kept in balance, we don’t know which side might seem to sink from the sheer weight of it.

- Recycling steel is known to be the chief reason architects consider it for green building. It is the best and the most recycled material in the world.

- Noone can deny its durability and it is one of the best durable materials around apart from being the most stylishly used material.

- With steel, there can be a massive reduction in the construction time.

- Energy efficiency and cost can come down imaginably with the use of steel.

- Carbon emission reduction and energy cost reduction are massively cut through the use of steel in construction and is one of the best sustainable materials for building in 2024.

Image credit: Thoughtco.com

7. Timber Homes

Timber is also another useful element for making sustainable homes. But timber is resourced from fine woods and chopped trees. It is one of the finest houses that timber can make but a personal recommendation from our end would not include it. Since trees are dying and so is the Nature. One of the essential ingredients to keep Nature as it is will require trees. Thus, you can think of using anything listed here to make a home. A home is made by the humans who live in it and of course, if you can keep your home clean there is nothing that can stop you from having one.

You can make timber of both gymnosperms and angiosperms trees. Timber is definitely the best in the lot when it comes to maintaining appropriate insulation in our homes, and also when considering design and architecture, it does not need much.

8. Natural insulating materials for homes

- Sheep’s wool for cold climates: You can make the walls of anything and then cover them with sheep’s wool. Not only can cold country people survive better, but they can also require far less to spend on keeping themselves warm.

- Straw Bales to keep the cold out: Straw bales can also keep your home warm if you can use them aesthetically in your homes.

- Polyurethane rigid foam for hot and cold countries: Hemp and bamboo can be used for making the material and since it is a plant based one, you can always use it for green living. Keep the molds and pests away and use it for heat resistance and sound insulation. A perfect sustainable material for building in 2024.

Use of straw bales: Image credit: Ecobnb

9. Adobe is a hot favorite among many

Adobe is earth mixed with water and other substances which contribute to its increased resistance and flexibility. Use bricks made of Adobe instead of clay baked in a brick kiln and create houses with mud, Adobe, and mortar.

Messner Mountain Museum architecture designed by Zaha Hadid is an impeccable example of its use.

The Conciliation Chapel in Berlin, Germany is built of Adobe entirely.

Benefits of Adobe use would include the following;

- Individual brick units shrink before being placed on the wall and that way Adobe is one of the best sustainable materials for building. This process would prevent the shrinking of walls, and also keep them from cracking.

- Extremely durable and flexible, points which are absent with concrete.

- Adobe can offer appropriate insulation and adequate thermal mass.

- Highly fire resistant, Adobe is also extremely energy efficient.

Image: Ecobnb

10. Cork is a natural element

Cork can be grown quickly and has recently been recognized as a sustainable material that you can use to build your houses and homes.

Image credit: Designboom.com

There are several benefits of manufacturing cork homes. Here are a few given below;

- The tree can grow and keep producing more cork which can be harvested and the tree would yield more which means there can be a continuous supply of it.

- Flexible, resilient, and quite capable of sustaining pressure, it can be one of the most sustainable materials for building in 2024.

- Excellent noise absorber, cork can function in the best possible way for heat insulation.

- Cork will never rot as it does not absorb any water.

11. Hemp concrete

Lightweight and easy transportation is what is alluring architects to use hemp wherever it is found in countries and localities.

Hemp cretes are strong, offer great sound and thermal insulation, and never leave carbon footprints. It is carbon dioxide negative which means it will absorb carbon dioxide more than release it.

Also, hemp can be grown quickly which will mean the market demand can be met easily.

Image credit: http://www.astm.org

12. Eat and build mushrooms

Mycelium, the vegetative part of mushrooms combined with computational technology can weave wonders and can create bricks for homes. This photo is a 40 feet courtyard of the art gallery in New York at MoMA PS1.

Mix corn husks and mycelium together to create these incredible bricks. Once mixed, the mixture is added to the brick mold and they are then grown for five days at a stretch. Bricks are layered one above the other and through the use of an algorithm customized completely in this regard.

Even agricultural wastes can be used and the best part of the construction is that they are completely biodegradable.

Rice hulls can be used alongwith mycelium to construct bricks.

Image credit: Golda Arthur BBC

13. Ferrock

A relatively new product in the market, Ferrock is a combination of steel dust collected from the steel industry and iron rock chips left out from the industrial processes. The iron rock chips are usually used in landfills.

What can you expect if you mix iron and steel- a concrete harder than concrete itself?

Benefits that can make Ferrock the Generation Z product include the benefits mentioned below.

- Ferrock concrete emits carbon but is less than actual concrete.

- Resilience to weather is more than any other form of sustainable form.

Image credit: https://a3511.wordpress.com/

14. Timbercrete

Mix sawdust and concrete is mixed and it can reduce the weight of concrete making it lightweight and yet strong.

Image credit: Conserve Energy Future

15. Bricks from human urine- Editor’s Choice

The University of Cape Town found if sand is mixed with bacteria, you can get urease. Urease is an enzyme that can break down (through hydrolysis) urea into ammonia and carbon dioxide. Calcium carbonate can be produced in the mixture as the carbon dioxide reacts with the plenty of calcium which turns to calcium carbonate in large amounts. The longer the bacteria is kept on the brick, the harder the brick becomes, and its durability and tensile strength increase manifold.

Suzanne Lambert, a CapeTown University researcher has voiced her favor for these bricks as they can completely eliminate urine waste issues foraying towards a zero waste principle. Also, the bricks would be capable of making houses far more strong and energy efficient.

The calcification process is known as the microbial carbonate precipitation technique.

Mass production estimation of these bricks is unknown and it is still not known when they can be mass produced. Anyone searching for bricks 40% stronger than ordinary limestone bricks can always go for these.

Dyllon Randall, Lambert’s supervisor claims it is the same process as the one used for the sea shell formation in nature.

The earliest credit for the project goes to Jules Henze, a Swiss student who worked 4 months with Randall on the concept in 2017. Vukheta Mukhari, a civil engineering honors student in UCT conducted the tests and took over testing the material.

Image credit: Dezeen

Breakdown of the process

16. Roofing Shingles

Roofing shingles made from asphalt can save your day. Even laminated or weather wood roofing shingles can work well.

Overlapping elements used for covering the roof are widely in use and though not a new way an innovative carry forward way to building firm constructions in the future.

17. Zero-carbon cement

Limestone, calcium, silicon, iron, and aluminum cement can reduce carbon emissions by 5% when used in construction. It would be the best sustainable material for building in 2024 in places where natural elements still cannot replace the building industry.

There is even 0 cement concrete and can save 88% of CO2 emissions. Concrete Canvas and Cemfree are two companies already manufacturing such cement. Anglia Water has already used this zero-carbon cement from Cemfree.

Image credit: Newsatlas

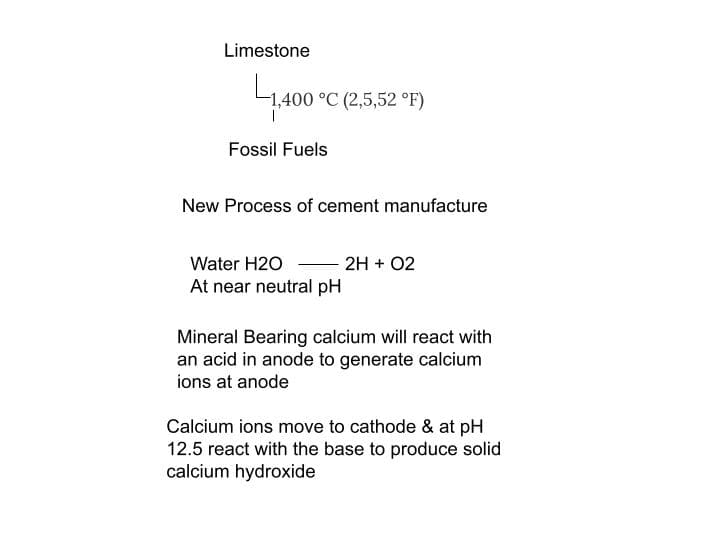

Instead of heating limestone to 400 degrees Celsius using fossil fuels, you can now use electrolysis to migrate calcium ions to the cathode once they are produced in the anode by a series of chemical reactions involving the breakdown of water into hydrogen and oxygen followed by reaction of the acid with a base.

In anode at 12.5 pH, calcium hydroxide is produced and is also known or has been ever since known as the builder’s lime or slaked lime.

Calcium can come from magnesium, silica, aluminum, and even iron.

Pictograph Breakdown of the process

18. Eat and build from potatoes but never become a couch potato

Chip[s] Board® is into making products from potato scraps. It will heavily cut down on food waste and globally 1.3 billion tons of food gets wasted every year. The UK company is inspired by a circular economy and the food waste is used to generate sustainable building materials.

19. Air purifying façade

Pureti-treated panels are placed on Neolith and produce hygroscopic and photocatalytic ways to react with sunlight and moisture in the air.

PureTi is nothing but 99% water and 1% encapsulated water with nano titanium oxide.

Does pollution have ways of reduction? Does the future have hopes? We can only hope it has.

Here we discuss 19 sustainable materials for building and construction for 2024. Consider them as a designer, builder, and people who want to live opulently and differently by contributing positively to the environment.

Self-cleaning is what we can easily do with PureTi. We are out into the new world!

Image credit: Inc.

Wrap Up

Here is what we can understand about building and the next-generation sustainable materials for building from here. Consider them as they can save your day and pocket, give you a home, a much more beautiful one than you can make one for yourself with concrete. Think out of concrete and surround yourself well to live well in this age of pollution and environmental decay and yet add meaning to the world.

You must be logged in to post a comment.